3.7. Clarifying responsibilities and improving approvals

Then there is the issue of changes to requirements, and the costs that they impose on the system. Everyone knows that it is so much easier and much, much cheaper to change something when it is a paper or computer design, than when it is half built in a factory. It is also the case that it is hard to see everything in advance, and so some questions only arise part way into the life of any project. It is equally true that new technologies can arise in the course of a long project, and it would be desirable to inject these into the system that one is acquiring.

This process has to be rigorously controlled, for fear that it can cause the costs and timescale of a project to spiral out of control, and that it can undermine the contracting basis of a project. If, for example, constant changes are made to a system at the request of the military customer, then the contractor has every right to change the price of his product.

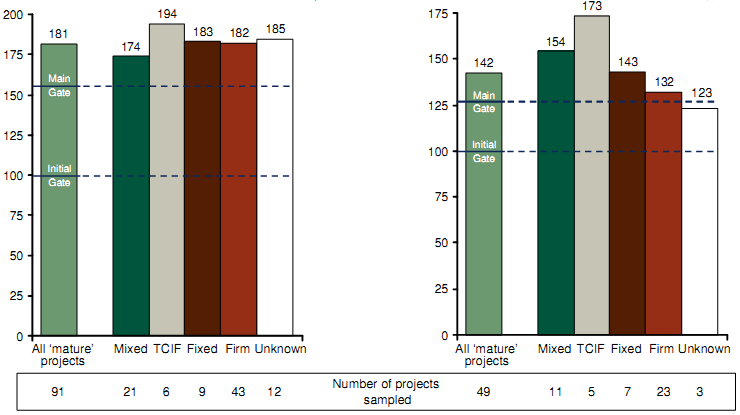

It can be difficult to determine whether such cost changes are solely the result of the requirements change, or are used by industry as an opportunity to sweep up other over-runs in cost that have happened elsewhere. If such changes happen frequently within a project, and there is evidence to say that they do, then it makes a mockery of a competitively procured, fixed priced deal. This effect may offer some explanation as to why Target Cost Incentive Fee ("TCIF") type contracts perform so poorly and why fixed / firm priced contracts undertaken by the MoD do not fare better than they do: the basis on which these contracts are let are undermined by requests by the MoD for specification changes and delays (see below) to expenditure timetables.

Latest forecast project duration overrun by contract type* | Latest forecast project cost overrun by contract type* |

Index of project duration (Forecast at Main Gate50 = 154) | Index of adjusted unit cost (Forecast at Main Gate50 = 127) |

| |

Note: Straight average shown; Projects more than 75% complete at latest forecast; * Analysis of difference by segment is based on growth during D&M phase only

Source: CMIS (Feb 2009); NAO Major project reports; IAB; Review team analysis

Figure 3-6: Project performance by contract type

At the very least, any specification changes or delays as a result of cash budgetary pressures should be clearly costed and documented, so that senior figures, up to and including the Executive Equipment Committee, can make a judgement about whether the changes are worth the costs.

All this presupposes that the Capability Sponsor is sufficiently skilled to define requirements, steward them over time, make trade-offs, and participate effectively in a disciplined project and programme management process which needs, as indicated variously up to this point and emphasised later, a more significant financial element. This suite of activities suggests a range of training akin to that in Defence Equipment and Support ("DE&S") to deliver successful projects and programmes: more of which later.

It is therefore the fourth key recommendation of the Review team that there be a clarification of the roles of the Capability Sponsor and DE&S organisations and the creation of a real customer/supplier relationship.

This requires the creation of a formal, proper interface between the requirements community and DE&S requires clarity of responsibility and accountability. DCDS(Capability) should be responsible for the creation and control of requirements, and required to control the budget of the new agreed and affordable equipment programme as a single point of MoD contact with DE&S for equipment so there is a clear customer / supplier relationship.

Within that overall structure, a single individual within the DCDS(Capability)'s team should have ownership of each project / requirement.

DE&S would then become the supplier responsible for programme management and delivery against the agreed requirements specification and budget.

Changes to requirements are inevitable to some degree, and programme delays will also occur, but these should be specifically costed by DE&S and included in the next iteration of the plan by DCDS(Capability) to be tested as to its affordability, which, if threatened would lead to cuts elsewhere.

The project approval process also needs greater clarification as part of this overall process, as well as greater consistency in its application. It is therefore the fifth key recommendation of the Review team that there be revision of the approval processes, with the intention of improving decision making.

The IAB should report to the Executive Committee on control of equipment approvals with a requirement to consider the affordability of the total programme as well as individual projects. The Chair of the IAB should be taken in by the MoD DG Finance.

Business cases should be prepared with a more consistent methodology. Mandatory use should be made of parametric data, independent cost estimates and other "should cost" tools as part of their preparation. The forward programme should reflect the systematic under-forecasting during the early stages and should be costed at the 90th percentile of estimated cost. The scrutiny community should be expanded / upweighted with commercial skills to provide additional early advice to IPT leaders in business case preparation.

The current Initial Gate / Main Gate approval process should be retained and the costs associated with these approvals should be included in the overall plan.