E.7.1. Managing the EPP under constrained conditions

Should spend be constrained each year, the planned expenditure will either have to be re-profiled (deferring expenditure to a future date) or capability removed from projects.

Cohorts of projects can be delayed to meet in-year budgetary constraints, but there are additional costs incurred in doing so. Overheads (both in MoD and Industry) need to be maintained throughout delays, resulting in reduced proportions of 'productive' spend.

Alternatively, cost reductions can ensure the programme meets in-year budgets, but this will be ultimately at the expense of reduced delivery of capability. In practice, cost reductions will be targeted at projects that have not yet entered manufacturing phase (i.e., well before ISD) - this will cause

more significant reductions in capability earlier in the project. Development costs are more likely to inflate, which may mean production costs are squeezed (e.g., by reducing capability).

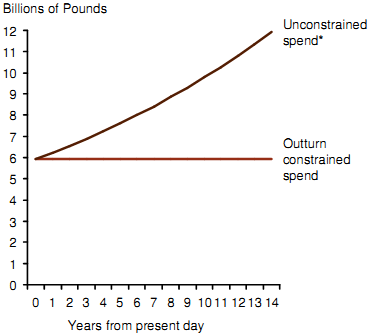

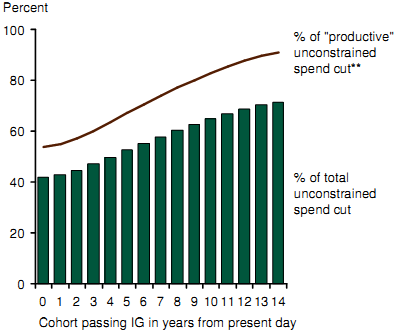

Assuming that capability is removed only from projects before they enter service and the amount of approved spend increases exponentially, then, as Figure E-6 shows, c.40-60% of spend needs to removed from cohorts of future projects (either through removing capability from or cancellation of projects in the cohort). This implies removing c.60-80% of the productive spend from those cohorts of projects.

(a) Exponential increase of unconstrained spend vs. the outturn constrained spend | (b) Proportion of unconstrained spend cut when cutting pre-ISD cohorts to meet budgets |

|

|

Note: * Unconstrained spend driven by exponential increase in defence inflation (with exponent of 5%);

** Based proportion of approved production cost vs. total cost for n=17 in CMIS of 78%Source: Review team analysis

Figure E-6: (a) Unconstrained spend profile resulting from exponential increase of the amount of expenditure approved each year and the assumed outturn constrained spend. (b) Proportion of unconstrained spend cut when removing capability from pre-ISD projects to meet the constraints. Note: ** Based on an estimated proportion of approved production cost vs. total cost of 78%.

This highlights the process that must go on in each planning round: programme costs and available expenditures are brought back into temporary balance either through trimming capability within projects in the plan, or occasionally, through outright cancellation of projects.