Alternative Project Delivery Approaches

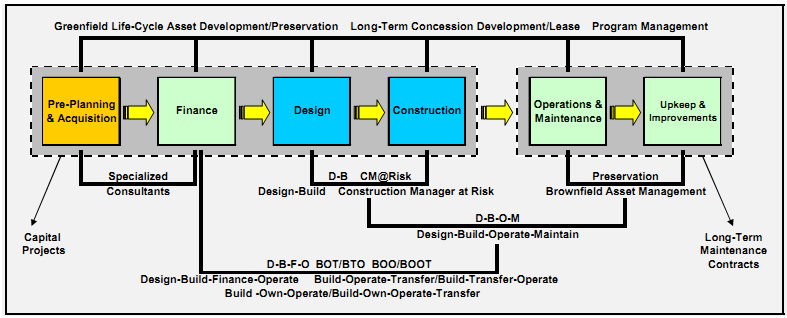

Exhibit 2.5 summarizes the major phases that comprise the delivery of infrastructure projects. Different project delivery approaches can be developed by combining various phases together that the private sector takes responsibility for. The primary combinations are discussed below, starting with Design-Bid-Build which is not considered a PPP approach since it is the traditional project delivery approach used in the United States with no increase in private sector responsibilities or risks.

Exhibit 2.5 Major Phases of Infrastructure Project Development and Delivery

|

|

| Source: Pekka Pakkala. Innovative Project Delivery Methods for Infrastructure - An International Perspective. Finnish Road Enterprise, Helsinki, 2002, p.32. |

• Design-Bid-Build. Design-bid-build (DBB) is a traditional form of project delivery where the design and construction of the facility are awarded separately to private sector engineering and contracting firms. As a result, the DBB process is divided into a two-step delivery process involving separate phases for design and construction. In the design phase, the project sponsor either performs the work in-house or contracts with an engineering and design firm to prepare the preliminary engineering plans and environmental clearance, which results in a project plan at the 30 percent completion stage, and the final drawings and specifications for the project. Once the design phase is complete, the project sponsor separately contracts with a private construction firm through a competitive bidding process. Under a DBB contract, the project sponsor, not the construction contractor, is solely responsible for the financing, operation, and maintenance of the facility and assumes the risk that the drawings and specifications are complete and free from error. The DBB selection process is based on negotiated terms with the most qualified firm for the design phase; while, the award of the construction contract typically is based on the lowest responsible bid price.

The DBB delivery approach was developed in the late nineteenth century as a way to deal with increasingly complex and specialized design and construction services; the perceived need to provide a check and balance between the development and execution of project plans; and a desire to deliver projects at a minimum cost. Many surface transportation projects still use the DBB approach.

The primary benefits associated with DBB delivery are:

- Division of work by specialization of effort (design versus construction);

- Reduced potential for collusion between the design and construction firms during the project delivery process that circumvents the contract terms; and

- Increased ability of local firms to compete for contracts which are more limited in scope and often smaller in scale.

By having separate contracts for design and construction, it is easier for smaller or specialty firms to compete with larger firms for the design or construction contracts, resulting in more bidders and frequently a more competitively priced bid.

• Construction Manager-at-Risk. Construction Manager at Risk (CM@Risk) is a project delivery approach in which the construction manager (CM) is brought into the project development process under separate contract during the design phase to minimize risk for all parties involved in a project by combining the experience, creativity, and skill of the engineering design and CM@Risk firms with the client's understanding of the project's requirements. In CM@Risk, the client selects the CM based on qualifications, not price, to provide constructability, technology, pricing, and sequencing analysis of the design. The CM becomes the design-build contractor when a guaranteed maximum price is agreed upon by the project sponsor and the CM.

CM@Risk includes construction management services for a project throughout the preconstruction and construction phases by a firm which is licensed as a general contractor and guarantees the cost of the project. CM@Risk is gaining popularity due to the following benefits:

- Collaboration of the client, designer, and CM to ensure a constructible design that is executed to meet the client's requirements;

- Continued advancement of the project during price negotiations;

- Potential for more optimal teaming because the CM can negotiate will all firms, rather than having to select from a limited number under DB delivery;

- Higher level of direct client involvement than other alternative project development approaches (described below) during project development phases as a collaborator with the design and construction management firms; and

- Reduced project risk by identifying design errors or omissions before they convey to the construction phase and guaranteeing the cost of project.

• Design-Build. Unlike DBB where the design and construction of projects is procured in two separate contracts with little or no overlap in the respective project work phases, the DB delivery approach combines the design and construction phases into one, fixed-fee contract. Under a DB contract, the design-builder, not the project sponsor, assumes the risk that the drawings and specifications are free from error. While the design and construction phases are performed under one contract, it is important to note that the design-builder may be one company or a team of companies working together. The DB selection process may be based on a negotiation with one or more contractors or a competitive process based on some combination of price, duration, and qualifications. Increasingly DB contracts are being awarded on the basis of best value, considering each of these factors. DB is a successful, well-established process for delivering major capital projects by both the public and private sectors in many countries overseas. DB offers cost-effective project delivery in terms of schedule, cost, and quality. The primary benefits that have been associated with DB delivery approaches compared to traditional DBB delivery include the following.3, 4, 5

- Time savings - The potential for time savings results from early contractor involvement in the design phase, which increases the constructability of the design plans; the ability to work concurrently on the design and construction phases for portions of the project; and the elimination of the bidding process between the design and construction phases that is required of traditional DBB project delivery.

- Cost savings - The potential for cost savings results from continued communication between design, engineering, and construction team members throughout the delivery; reduced inspection requirements by the project sponsor since the design-builder is responsibility for these activities, reduced change orders due to early contractor involvement in the design phase; and shortened project timeline.

- Shared risks - Since the potential project risks are shared among the public and private sectors, the risks may be assigned to the party best able to handle them. For example, the private sector may be better equipped to handle the risks associated with design quality, construction costs, and delivery schedule adherence since they are responsible for both the design and construction of the facility; while, the public sector may be better able to manage the public risks of environmental clearance, permitting, and right-of-way acquisition.

- Improved quality - The potential for improved quality results from the involvement of the design team through the project development and opportunities to incorporate project innovations and new technology that may arise based on project needs and contractor capabilities.

DB project delivery may include a variety of structures and combinations that result in private participation only in the design and construction phases or may extend into operations, maintenance, and project financing. These variations of the DB delivery approach are discussed in greater detail below.

• Design-Build with a Warranty. Under the Design-Build-Warranty (DB-W) approach, the design-builder guarantees to meet material, workmanship, and/or performance measures for a specified period after the project has been delivered. The warranties may last five to 20 years. The potential benefits of the DB with a warranty approach include the assigning of additional risk to the design-builder and reducing the project sponsor's need for inspections and testing during project delivery.

• Design-Build-Operate-Maintain. Under a design-build-operate-maintain (DBOM) delivery approach, the selected contractor is responsible for the design, construction, operation, and maintenance of the facility for a specified time. The contractor must meet all agreed upon performance standards relating to physical condition, capacity, congestion, and/or ride quality. The potential benefits of the DBOM approach are the increased incentives for the delivery of a higher quality plan and project because the design-builder is responsible for the performance of the facility for a specified period of time after construction is completed.

• Design-Build-Finance-Operate. The design-build-finance-operate (DBFO) delivery approach is a variation of the DBOM approach. The major difference is that in addition to the design, construction, and operation of the project, the contractor is also responsible for all or a major part of the project's financing. The potential benefits for the DBFO approach are the same as those under the DBOM approach and also include the transfer of the financial risks to the design-builder during the contract period. While the project sponsor retains ownership of the facility, the DBFO approach attracts private financing for the project that can be repaid with revenues generated during the facility's operation.

• Build-Operate-Transfer / Build-Transfer-Operate. Build-operate-transfer (BOT) is similar to the DBFO approach whereby the contract team is responsible for facility design, construction, and operation for a specified time, after which project ownership and operation is returned to the project sponsor. Under a BOT approach, the project sponsor retains facility ownership as well as the operating revenue risk and any surplus operating revenues. Under the similar Build-Transfer-Operate (BTO) approach, asset transfer occurs after construction with the private provider continuing to operate the facility under the BTO contract. The potential benefits of using a BOT or BTO approach are similar to the benefits associated with using a DBOM contract: increased incentives for the delivery of a higher quality plan and project because the contractor is responsible for the operation of the facility for a specified time period after construction.

• Build-Own-Operate / Build-Own-Operate-Transfer. Under a build-own-operate (BOO) delivery approach, the design, construction, operation, and maintenance of a facility is the responsibility of the contractor. Under the similar Build-Own-Operate-Transfer (BOOT) approach, asset transfer occurs after a specified operating period when the private provider transfers ownership to a public agency. The major difference between BOO and DBOM, DBFO, BOT, and BOOT approaches is that ownership of the facility remains with the private contractor. As a result, the potential benefits associated with a BOO approach are that the contractor is assigned all operating revenue risk and any surplus revenues for the life of the facility.

____________________________________________________________________________________

3 Loulakis, M. C. Construction Project Delivery Systems: Evaluating the Owners Alternatives, AEC Training Technologies, 1999.

4 Pakkala, Pekka Innovative Project Delivery Methods for Infrastructure: An International Perspective, Finnish Road Enterprise, 2002.

5 Tenah, K. A. "Project Delivery Systems for Construction: An Overview," Cost Engineering, AACE International, Morgantown, WV, 43(1), pp 20-26.