2.4.1 TYPICAL SELECTION METHODS

Another desire of this project was to summarize what the percentage of price and what percentage of quality (other parameters) should be used and what attributes should be used in the tendering contracts. Since there was not enough response and data to develop these figures, they are not included in this report. However, here was enough data on maintenance contracts and are discussed in the "Maintenance Practices" section of this report. However, based upon comments during the interviews there was a overwhelming majority not desiring to use the low-bid method.

| MODEL | PRICE RANGE | QUALITY |

| 70-100% | 0-30% | |

| 50-100% | 0-50% | |

| CM | 70-100% | 0-30% |

| ~70% | ~30% | |

| Typically Lowest Price | B.C. Canada has Included Innovations & Quality via an Upset Price | |

| Alliance | 0% | 100% |

Table 9 Typical Variations in Contractor Selection Criteria

The selection process always seems to bring debate as to what should be the range of price versus other factors, tendering costs, what attributes should be measured, and the believers of the "Low Bid" system. It is very difficult (or impossible in some cases) to measure the Quality Control (QC) plans, determine the best design solution when using Design-Build, and what innovations are proposed when using the low bid (lowest price) method. The low bid method does not take into account anything but price. Therefore, the low bid method overlooks the following aspects as well as other things.

• Evaluating best design solution proposed

• Innovations or Alternative Technical Concepts (ATC)

• Project Manager's skills (extremely important)

• Environmental considerations

• Technical skills

• Traffic management & proposed traffic diversion

• Supply chain management & skills

• Allocation of risks

• Evaluation of "Quality Plans"

• Ability to perform project and proposed solution or methodology

• Early completion

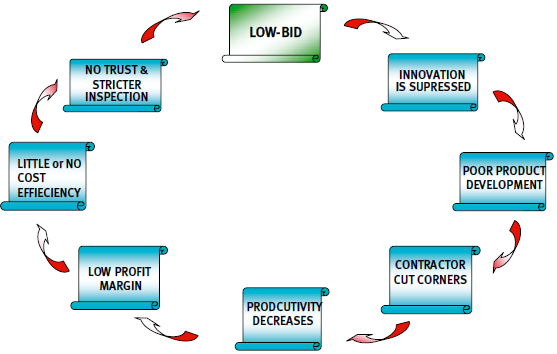

There is another aspect of the low bid system that can easily be understood in Figure 9. The purpose is not to make extra work for the contracting industry or to change the marketplace, but to find the better forms of teamwork, getting quality work (see section 2.5) done right the first time, better innovations, problem resolution versus problem escalation attitudes, partnering, good leadership practices, accountability, and most importantly a good value for the public users and taxpayers (getting Value for Money versus lowest first time costs). Also, many clients around the world realize that in order to have a competitive and viable contracting industry for the future, the industry must now begin to make a reasonable profit margin to retain future marketplace survival (beneficial for all parties & supply chain). Then the issue becomes how to measure subjective information objectively. This is a key point and the clients could work together with the industry to determine real and excellent means to measure these "Quality Criteria" in the selection process. It should be fair, measurable, appropriately weighted for each attribute, transparent, and applicable to the local legal requirements. One observation from several contractors in the study was that of accountability. Accountability for each organization's role is important and includes the client being responsible too.

| Infra-Sector "Circle of Regret" |

|

|

Source: Finnra (2003)

Figure 9 Low-Bid Circle of Regret

Most understand that DBB and CM models are easy to tender, and the commercial transaction cost are quite low. This may be one reason why the construction industry desires the DBB method as it is easy to bid and easy to evaluate as it is the lowest price for a viable submitted tender. It is a simple system and quite easy to understand and tender. However, there is not enough satisfaction especially with clients and Figure 9 also shows some of the issues with the lowest bid method.