3.7 Quality

Quality is an important part of the process and the maintenance aspects do not receive the same level of care as capital projects. Quality can also be quite subjective and depends upon the "eye of the beholder", especially when the "road user" is concerned. Customer perception levels are quite often at a different level as compared to the perspective of the road authorities. Most road authorities have some form of quality systems in place and specify the "Level of Service" (LOS) or often known as the "Performance Specifications or Functional Requirements". In routine maintenance contracts it is very difficult to measure all the actual service levels achieved, because it would require an extremely large amount of data collection and analysis, and these are usually obtained via visual type measures. This is especially true for the winter maintenance and it is not feasible yet even though it is a very important safety issue.

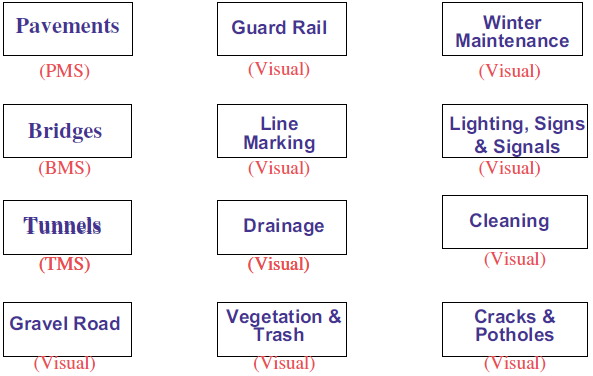

Figure 16 shows an example of the large amount of visual activities needed and one can visualize the large amount of data needed to collect from these various maintenance activities. Several countries do in fact measure the performance of routine maintenance activities and typically evaluate approximately 10% of the data to extrapolate statistical performance results. Often statistical analysis tools assist the assessment of the various maintenance activities to determine a condition survey of these assets. Some even publish road and asset condition evaluation in some form of maintenance condition survey and reports. Also, some countries determined that it was not important to measure these parameters, and apparently reverted to the results of overall customer satisfaction surveys. For example, Finland uses a Pass/Fail system along with a customer service survey and national telephone complaint system to report any deficiencies.

There have been good systems and maintenance management tools developed for tunnels, bridges and pavements. There are systems that are very objective and include Bridge Management Systems (BMS), Tunnel Management Systems (TMS), and Pavement Management Systems (PMS). These are periodic maintenance aspects that typically are tendered via separate contracts.

|

|

Source: Pakkala (2005)

Figure 16 Large Amount of Visual Data Needed

Based upon the surveys and interviews from the various road authorities and service providers there have been very innovative practices and approaches to retain the public values and quality. Some of these are quite simple and may outwardly appear obvious, but they can really affect the quality levels when implemented correctly. The subsequent list highlights the main techniques and practices that were used to retain the public authorities' quality values.

• QC and quality plans by contractors (contractual agreement)

• In order to Increase quality - increase inspection (costly)

• Simple solution - raise the quality specifications or standards

• Training of contractors & subcontractors (pre-season & kickoff meetings)

• Strict penalties for non-performance after repeated failure (however - creates lack of trust)

• Using Quality Based Selection (QBS) criteria for contract award

• Automated customer complaint feedback system automatically directed to the service provider

• Customer surveys

• Good communication - meetings, problem resolution, & focus groups (or road charters)

• Partnering - project level & strategic level or partnering board

• Guidance handbook

• Maintenance Rating Program (MRP) or statistical evaluation of assets

• Some form of interactive web-based, automated, & flexible "Maintenance Management System"

• Good software tools (billing, scheduling, & inspection)

• Monitoring the performance of the subs

• UK - Performance Review Improvement Delivery (PRIDE)

• Western Australia has a performance review framework to measure and assess the contractors performance against contract objectives (can use also to drive performance & decision making)

• Having some type of Continuous Improvement Process (CIP) - UK

• Post performance evaluation of service providers

• Contractor rating system that includes post evaluation

• Semi-annual or annual evaluation of assets (client & contractor)

• Have a modern/innovative Road Weather Information System (RWIS)

• GPS systems for monitoring snow plow activities (Finnish Keiju system)

When QC is relinquished to the contractor, then the QC plans are essential as they will determine the standard of practice used by the contractor for that entire project duration. This also becomes a contractual obligation. In most countries the QC led by the contracting authority is working reasonably well, but for others it is learning process and requires some degree of development and fine tuning.

As noted above, there is also a simple solution to improve quality, but it would be an expensive alternative. Simply raising the minimum technical and performance standards would provide higher quality levels or the other alternative is to increase inspection to verify that the quality demanded is actually being implemented. Both these simple solutions would probably cost more and it would be difficult to gain acceptance in the client organizations and amongst the funding authorities. These alternatives are probably not likely since the most road authority organizations are downsizing, gradually losing experience and expertise, and lack the resources.