CASE STUDY 2

CASE STUDY 2 | ||||||||||||||||||||||

Field Electrical Power Supplies (FEPS)

One of the 1347 generator sets provided by Genistics.

|

The contract was necessary as the existing equipment was approaching the end of its useful life and did not meet health and safety legislative requirements

12 The Field Electrical Power Supplies contract was let to provide generator sets to support operational electrical requirements in the field. The contract was necessary as the existing equipment was approaching the end of its useful life and did not meet health and safety legislative requirements. In addition the existing system was outdated. Its thermal (heat) and acoustic (sound) signatures were high compared to more modern military equipment, making it more liable to detection by enemy forces. It was also unreliable and had poor mobility.

13 The project started in 1996. Two bidders were short listed at the prequalification stage in April 1997 and Genistics was selected as preferred bidder in July 2000.

14 Unlike other PFI projects the Department specified the technical requirement in detail in a manner similar to a conventional procurement. They produced a detailed requirements specification indicating exactly how many generator sets were required and the standard that they were to be built to. Typically in PFI the customer specifies the outputs and the suppliers then choose the best solution to meet the specified criteria. By specifying the inputs the opportunity for innovation is reduced, which could impede value for money.

A preferred bidder was appointed while the commercial arrangements had not been fully agreed

15 Genistics was appointed preferred bidder before the commercial arrangements had been fully agreed and subsequently the commercial agreement had to be negotiated. As a result, the preferred bidder stage took 23 months to reach an acceptable agreement. These negotiations were made without the benefit of competition. PFI projects should have a mature commercial solution agreed in principle before a preferred bidder is appointed. Under the new system of competitive dialogue this will be an even more important consideration.

16 During the preferred bidder stage, Aggreko, the subcontractor who was proposed to provide the fleet management services of the contract, withdrew from the contest. ABRO, who are part of the Ministry of Defence, but are a trading fund, stepped in and a sub-contract was agreed with Genistics.

Problems with the design were identified two years after the prototype had been accepted by the Department

17 Once the contract was signed a prototype was made available to the Department for trials. Validation testing and user trials took place in 2002 and 2003. After acceptance Genistics started the mass production of the 1347 Generator sets. The deployment of the generators began in May 2003 however in October 2003 it was identified that, for certain Ministry of Defence vehicles, there was an interface issue that made them incompatible. This made the vehicles unsafe when turning corners. The solution was to extend the 'A' frame connecting the generator to the towing hitch at the expense of mobility. As these particular vehicles are widely used by the Department this was a problem which needed to be resolved, particularly as the generators were needed on front line operations.

18 The contractor in a gesture of goodwill agreed to waive their exclusivity clause to allow the Department to use their existing stock of generators whilst the whole fleet of generators was modified. An acceptable design had been obtained by extending the 'A' frame by 650mm. Once the modification was agreed the generators were rectified. Between April 05 and March 2006, 80 per cent of the fleet were modified with the last 20 per cent being modified by March 2007. The cost of the modification was £7.3 million.

19 Although the modification solved the majority of the Department's problems with the interface with the existing fleet of vehicles, the Department are currently replacing many of its vehicles. The project to replace the 16,000 fleet of four, eight and 14 tonne cargo and recovery vehicles is well underway with the first shipment of 1285 vehicles entering service for training in Autumn 2007 with full service being achieved in 2008. Further deliveries will be made between 2008 and 2014. These vehicles are not fully compatible with the Field Electrical Power Supplies as the height of the towing eye could impede safety and the wiring will need modification. It is therefore possible that the Field Electrical Power Supplies fleet will have to be further modified to address this issue.

The equipment is being used outside of its defined operational parameters

20 The Field Electrical Power Supplies equipment is being used outside of its defined operational parameters. In Iraq temperatures are above the level specified in the contract (450C was specified but actual temperatures exceed 500C). The dusty environment is also outside of the specified parameters. These factors may impact performance indicators and may mean that the supplier will be able to claim that latent defects have arisen from the assets' use outside of the specified environment. The Department will have to bear the cost of the additional wear and tear.

21 There are other costs that have been incurred by the Department arising from damage caused to the generators. These range from traffic accidents to minor incidents such as losses of tools and keys. The cost to the Department approximates to £0.5 million per annum. These incidents would have arisen in the past - and would also likely arise under a conventional procurement - however under PFI the costs are more visible. Under the contract, the Department only has the option to ensure that the generators are fully repaired because the generators always have to be in the condition specified in the contract. This has the benefit of ensuring capability is maintained but reduces the ability of the Department to defer expenditure.

22 In addition to the repairable damage to the generator, seven sets have been destroyed - some due to hostile action in Afghanistan. When a generator is destroyed the Department has to pay the contractor for that generator until the end of the contract or until the Department purchases a replacement generator. As it is inefficient to replace the generators on a piecemeal basis, the Department has decided to delay the replacement until 2008/09 (five years into the contract) and then purchase 15 sets. This will ensure that the Department has a stock of generators to call on when and if other generators are lost.

Both sides have had to bear further unexpected risks

23 The generators have, in a number of isolated cases, caught fire. The cause of the fire is partly down to misuse and not following documented procedures, exacerbated in the view of the Department, by the design of the generators. This was an area for dispute with the contractor. However, having taken legal advice, it was agreed that since the Department specified the design of the generator and had tested and fully accepted the generators there would be no liability to the contractor.

24 Some risks have remained with the contractor: a fire at one of the premises used to store spares resulted in a payment deduction of £41,000. In addition there have been other payment deductions for not meeting Key Performance Indicators (KPIs), however the reliability KPIs have not been triggered and the number of call-outs are lower than anticipated. However reliability may become more important in the later stages of the contract.

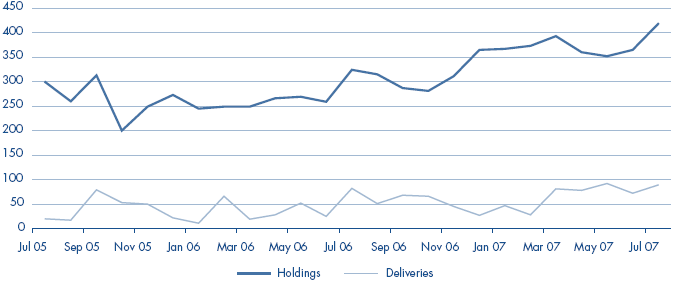

25 The contractor has also had to bear the cost of storing generators, as the usage has been lower than the expected level of 1189 (just under 90 per cent of the total 1347). In addition, the number of moves - where ABRO collects or delivers generators - is higher than planned, which may indicate that the equipment is being used differently than expected by Army units. Both moves and holdings have also increased since the contract became fully operational.

Risk management procedures are in place

26 The Department did not use formal risk procedures in the procurement phase of the contract. However in the operational phase the contractor and the Department use a joint risk approach to managing the contract. Risk is tabled at regular project review meetings and considered an important way of managing the contract. ABRO also maintains its own risk register.

22 | Both the number of moves and the number of generators held in store have increased |

Source: Ministry of Defence | |