LCR Case example

In February 1996, DfT awarded a contract to London & Continental Railways Limited (LCR) to build the Channel Tunnel Rail Link (the Link), a high speed railway between St Pancras Station in London and the Channel Tunnel. It was also awarded responsibility for running the British arm of the Eurostar international train service (Eurostar UK). The project was split into two sections as a result of negotiations between LCR and DfT for public sector funding. Union Railways (South) Ltd and Union Railways (North) Ltd are the subsidiaries of LCR acting as clients for Section One and Section Two of the project, respectively.

RLE is employed by Union Railways (South) Ltd and Union Railways (North) Ltd for the engineering, procurement of construction contracts and construction management of Section One and Section Two of the project, respectively. RLE is paid its actual costs plus profit and a bonus (or penalty) paid against target out-turn cost for the design and construction.

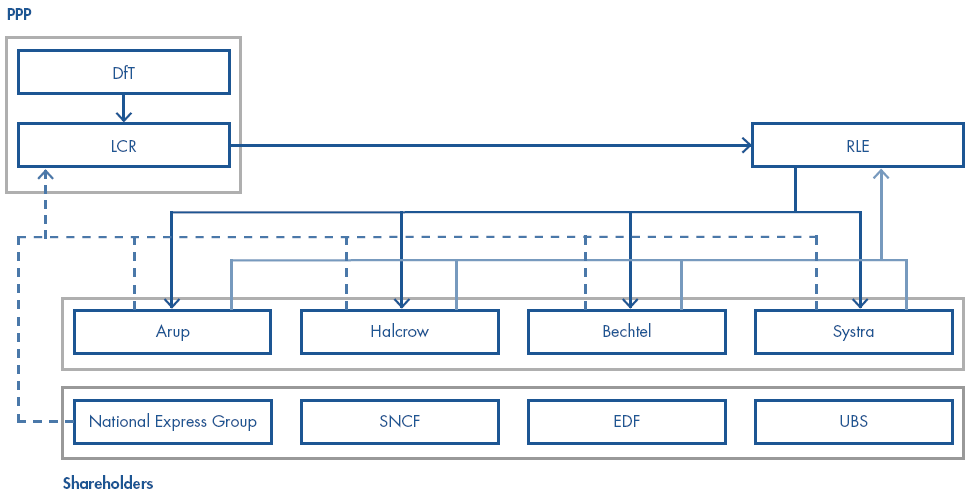

LCR's supply chain therefore had a similar structure to Metronet and its Trans4m subcontracts (Figure 27). RLE, responsible for project management, is held by four of LCR's shareholders, and sub-contracts exclusively to those four companies. But contrary to the Trans4m case, this supply chain has delivered successfully. There are two key differences with the Metronet case: additional shareholders and close partnership working.

Beyond the shareholders that formed RLE to establish the tied supply chain, LCR had additional shareholders, which may have brought added discipline to RLE's delivery. In Metronet's case, all its shareholders were part of the tied supply chain.

The conduct of project delivery seems to have been one of genuine partnership between all parties. For instance, Ernst & Young identified "close interaction between RLE's and its contractors' project management teams including the use of shared offices. Around 800 staff of RLE and its contractors were co-located in offices in central London." Ernst & Young further observed "a policy of total openness" between RLE's staff and that of the contractor. Offices, databases and cost information were shared. RLE even had access to the contractor's bank account for the Project as well as the contractor's statistics on productivity, plant, number and quality of employees.7

27 | London & Continental Railways Limited tied supply chain structure |

Source: National Audit Office | |

__________________________________________________________________________________________

7 Freshfields Bruckhaus Deringer and Ernst & Young, Report for the Office of the PPP Arbiter, Contract Management Study - Phase One, October 2005.