9.2 REASON FOR THE COLLAPSE OF THE WALL AT OXGANGS SCHOOL

9.2.1 It is the view of the Inquiry that the primary cause of the collapse of the wall at Oxgangs School was a direct result of poor quality construction, in the building of the external cavity wall which, in the case of a significant proportion of the wall ties failed to achieve the required minimum embedment of 50mm, particularly in the outer leaf of the cavity wall. The poor quality relates to all three of the following aspects:

• the direct laying of the bricks and the poor positioning of the wall ties in the mortar bed;

• inadequate supervision of the laying of the bricks and the positioning of the wall ties in the mortar beds; and

• the quality assurance processes as implemented by sub-contractors and main contractors to confirm the quality of the construction of the walls.

9.2.2 All three issues were ultimately the responsibility of the contractor in charge of the site.

9.2.3 Based on the analysis presented in the 'Oxgangs Primary School: Report on the Gable Wall Failure' produced by Will Rudd Davidson, dated 29th February 2016, it is reasonable to conclude that the outer leaf of the gable wall was not sufficiently tied to the inner leaf to allow it to act together with the inner leaf to resist the combination of positive and negative pressures that were applied to the wall as a result of the strong wind associated with Storm Gertrude. It should be noted that this Report was produced by WRD who were acting as advisors to ESP at the time and that it was not commissioned or its findings influenced by the City of Edinburgh Council.

9.2.4 It is also reasonable to conclude, based on the information in the meteorological records provided, that if the wall had been designed and built to the required appropriate standard it would have been able to withstand the level of wind loading to which it was subjected.

9.2.5 The recognised construction industry standard at the time of the construction of the PPP1 schools required wall ties to be distributed broadly as shown in Diagram 2 at paragraph 5.2.5. In addition to the general requirement of at least 2.5 wall ties per square metre, a second key factor in determining the strength of the tie of the outer leaf to the inner leaf is the depth of embedment of the wall ties, which according to the relevant British Standard should be a minimum of 50mm.

9.2.6 This 50mm requirement is considered very much a minimum figure. A leading manufacturer of wall ties recommends that embedment in the use of their wall ties should be between 62.5mm and 75mm. All competent building contractors and sub-contractors would be expected to be fully aware of the minimum requirement of 50mm whether or not it is specified in the project documentation.

9.2.7 In line with the standard minimum requirements, the specification produced by the design team for the Oxgangs School did also specifically require a minimum embedment of 50mm into the bed joint of both inner and outer leaves of the cavity walls in accordance with the requirements of the relevant British Standard. Therefore, in this specific regard the issue was not as a result of any fault in the specification.

9.2.8 The specification clauses provided in relation to the installation of the wall ties, as produced jointly by the architects for the Oxgangs School, Holmes Partnership, and the structural engineers, WSP were as follows:

"233 FIXING TIES IN MASONRY WALLS WITH PARTIAL FILL CAVITY INSULATION

• Bed not less than 50mm into bed joint of each leaf.

• Slope downwards towards the outer leaf with drip centred in the cavity and pointing downwards. Do not bend ties to suit coursing.

• Evenly space in horizontal and vertical rows (i.e. not staggered) at 900 centres horizontally and 300mm centres vertically, unless otherwise specified.

• Provide additional ties within 225mm of reveals of unbonded opening."

(It should be noted that the 300mm dimension specified above for vertical centres is not a practical spacing for blockwork and is most likely a typing error. This was probably intended to be 225mm, i.e. one blockwork course, as was indicated on several drawings produced by the design team).

9.2.9 The results of the structural survey undertaken by WRD, acting on behalf of ESP, led them to conclude in their Report dated 29th February 2016 as follows:

"A combination of excessive cavity width, related non-verticality, and incorrectly constructed wall ties has resulted in a cavity wall construction which in many of the ties had insufficient embedment of the wall ties in the outer leaf. This in our view is the primary contributory factor." (of the collapse of the wall)

9.2.10 The Inquiry has no reason to disagree with this analysis.

9.2.11 The fact that in further investigations a similar lack of adequate embedment of wall ties, to that reported in the survey of the gable wall at Oxgangs School, was subsequently discovered to be present throughout the rest of the external walls of Oxgangs School, and in a further series of investigations was found to be present throughout the remaining PPP1 schools, lends strong support to this being a realistic and accurate assessment of the condition of the wall and a prime cause of the collapse of the wall.

9.2.12 The reported variance in cavity width and the references to verticality issues in the blockwork inner leaf of the cavity wall are likely to have contributed to the lack of embedment of wall ties.

9.2.13 On the following photograph of the collapsed section of the Oxgangs gable wall, one can see against the remaining inner blockwork leaf, the use of diagonal flat steel bracing bars in one of the structural bays. In order to accommodate these bars, the blockwork in their vicinity had to be cut back or reduced to around 100mm thick in some locations as opposed to 140mm thick blockwork elsewhere. The staggered joint line of the reduced blockwork can be seen in the area encircled red.

9.2.14 The wall ties that were installed in this location can also be seen where they remained as the external leaf of brickwork was pulled outwards off the wall ties by the suction of the wind, the embedment of wall ties in the outer face being insufficient to resist this negative pressure.

9.2.15 Any wall ties in the reduced areas would have to span a cavity width of 160mm rather than 120mm. The specified 250mm long wall ties used would therefore be unable to achieve the minimum required embedment of 50mm to both leaves at these locations, (i.e. 50mm + 160mm + 50mm = 260mm), and any deficit in embedment would be exacerbated by any further occurrence of the defective construction that resulted in a widened cavity elsewhere in the wall or through greater than 50mm embedment in the inner leaf as the result of it being built first.

Image 23: Photograph of the collapsed section of the Oxgangs gable wall.

9.2.16 Part of the evidence provided to the Inquiry was information that the inner blockwork leaf of the cavity wall had been built prior to the construction of the outer leaf of the wall.

9.2.17 This has come to be a common approach adopted by builders anxious to quickly provide a dry enclosed envelope to the building so that internal trades can commence at an earlier stage of the construction process than they could otherwise do. Doing so, without taking appropriate additional quality protection measures, does however bring with it several risks to the quality of the construction, including specifically the lack of proper embedment of wall ties.

9.2.18 In the case of the PPP1 schools, the internal leaves of the panels of blockwork of the cavity walls were built between the steel columns of the structural frame of the building so that their internal face aligned with the internal face of the columns. If there had been any slight misalignment in the steelwork erected, as can occur and which, if within allowed tolerances, can be acceptable, then in order to ensure a consistent inner face of blockwork with the face of the columns, the bricklayers will have followed the line of the steelwork columns and beams rather than seeking to ensure that the walls were being built exactly plumb or in line. If the outside leaf is then completed later and is built plumb and to line, this can lead to variation in the width of the cavity between top and bottom of the wall and along its length, resulting in a possible widening of the cavity and reduction in the embedment of wall ties achieved.

9.2.19 A practical difficulty associated with constructing the inner blockwork leaf first, is that the wall ties are required to be built into the wet mortar bed of the inner leaf as the wall is built and be left with sufficient length projecting out so that the other end of the wall tie can be built with the correct embedment into the outer leaf when it is eventually constructed.

9.2.20 As the outer leaf is not yet there when the inner leaf is being built and the bricklayer is not able to see the actual cavity, there is not the same visual reference and reassurance that the wall tie is being placed, as required, equidistantly between the two leaves.

9.2.21 There is also a risk that the protruding ties may fall out due to either overbalancing as the force of their cantilevered weight could be stronger than the restraining force of the grip of the still wet mortar or as a result of being knocked out before the outer leaf is built. As a result, bricklayers, seeking to prevent this, can tend to place the wall ties further into the mortar bed of the inner leaf than required, potentially leaving an inadequate length projecting to allow the achievement of the minimum 50mm embedment in the outer face.

9.2.22 The type of wall ties used in the construction of the Oxgangs gable wall was a 250mm heavy duty strip tie of the type produced by a company called Vista, an example of which is depicted below.

Diagram 7: A Vista VT1 heavy duty wall tie similar to those used in the Oxgangs gable wall and clip for retaining insulation against inner leaf.

9.2.23 The Inquiry received evidence from an experienced technical services engineer employed by Ancon, one of the leading manufacturers of wall ties in the UK. He was asked, when shown one of the wall ties that had been recovered from the collapsed Oxgangs wall, how easily and successfully he felt this type of wall tie could be installed in the situation where the leaves of a cavity wall are built separately. He responded:

"Looking at the strip wall tie, this would be quite difficult to use if installing in the inner leaf first, before the outer leaf catches up. When placing one end of the tie in the mortar of the inner block, the tie would almost certainly overbalance before the mortar has had time to fully cure, due to the weight and projection of the tie itself. Sometimes, a bricklayer will embed the tie more on the inner leaf to stop this from happening."

9.2.24 To overcome the risk of ties falling before the mortar hardens, rather than embedding the wall ties in each joint as the wall is built, bricklayers have been known to push them into the still wet joints between blocks from the outside face. This is regarded as unacceptable practice, as the wall tie will create a void in the mortar as it is pushed in and as a result will not give the required degree of adhesion between wall tie and mortar to provide the required strength of connection between the inner and outer leaves of the wall.

9.2.25 A further risk, associated with building the leaves separately, is that as the leaves are built, potentially by different teams of bricklayers, the brick courses in the outer face may, as the wall rises, become out of alignment with those of the already built blockwork inner face. This makes the proper installation of the projecting wall ties into the outer leaf even more difficult. The heavy-duty ties which were used would prove particularly difficult to bend by bricklayers seeking to deal with any potential non-alignment of coursing between the two leaves.

9.2.26 In line with what was standard practice, the specification jointly produced by the architects and structural engineers on the original design team contained the following extracts from clauses:

"535 Height of Lifts

• Raise no portion of the work more than 1.2 m above another at any time

• Do not carry up one leaf more than 1.5 m in any one day unless permitted by the CA

545 Levelling of Courses

• Bring both leaves of cavity walls to the same level at every course containing vertical twist type ties or other rigid ties"

9.2.27 The Inquiry were advised as part of the evidence given by the architects, the Holmes Partnership, that failure to comply with this requirement had been raised by them initially during the construction of the Phase 1 schools. They advised that the circulated notes of a visit to site showed that this issue had been brought to the attention of both AMJV and the Tier 2 contractor Lilley Construction, during the construction of Pirniehall Primary School, a Phase 1 school.

9.2.28 The following is an extract from a written statement relating to this issue offered in evidence to the Inquiry by The Holmes Partnership (now Holmes Miller). (References to "CJV" are to AMJV):

"It appears Contractors, and the CJV, ignored this requirement, building the inner leaf first and following on building the outer leaf at a later date. The matter was highlighted in our Site Visit Notes from Pirniehall/St. David's on 5th April 2002, but was not acted upon and carried on through the course of the project. We had no power to instruct the CJV/Contractors to comply with our F10 specification; we could only highlight to the CJV/Contractors where there were deviations from the specifications"

9.2.29 As part of their verbal evidence, a Director of The Holmes Partnership, who had been directly involved in the projects at the time as an architect and associate within the practice added:

"…the Holmes Partnership had concerns due to worries about coursing and how the wall ties would be built in to avoid water being directed back towards the inner leaf"

and that:

"…it was not uncommon for the specification requirement to build both leaves in parallel to be ignored in D&B projects for programme reasons."

9.2.30 Evidence given to the Inquiry identified the bricklaying sub-contractor who built the wall that failed at Oxgangs School as VB Contracts. Despite several attempts, the Inquiry failed to receive a response to an invitation to give evidence sent to what is thought to be the current address of the person who was Chief Executive of VB Contracts at the time of the construction of Oxgangs School. VB Contracts was appointed by Miller Construction to build the masonry walls for all four Phase 2 schools. The company is reported as having gone into liquidation in 2008.

9.2.31 The Chief Operating Officer of Galliford Try, the company that acquired Miller Construction, in his evidence to the Inquiry in relation to the construction of the wall said:

"There is a reverse hierarchy of responsibility in regard to the way the wall had been built, and in my view the bricklayer who built the wall will have known that the wall had not been correctly built and that it had knowingly been left in an unsafe condition due to the embedment issues caused by the cavity variations."

9.2.32 When asked how it was that the Quality Management Systems in place had failed to identify these defects, the Chief Operating Officer replied:

"It was incumbent on each Main Contractor to ensure that the buildings had been built properly. It would be expected that a bricklayer should have brought the wall tie embedment issue to the attention of the main contractor. As a wall is closed up, then a supervisor would not always have the opportunity to inspect the cavity and the wall head restraints. There is always reliance on people doing what they are supposed to do."

9.2.33 The view of the Inquiry on these issues is that even though as stated every member of the construction team has a duty to carry out their responsibilities in an appropriate and conscientious manner, evidence would suggest, unfortunately, that this is sometimes not the case and cannot safely be relied upon to be the case.

9.2.34 Accordingly, systems must be employed by contractors that are able to provide the level of assurance required as to the quality of all aspects of the construction, especially in relation to those elements of construction the failure of which could result in injury to users of buildings.

9.2.35 It is the view of the Inquiry that the quality management systems, as implemented on the PPP1 projects, were insufficient to prevent the defective construction that could, in slightly different circumstances, have resulted in the fatalities of children.

9.2.36 The structural engineers appointed to support this Inquiry undertook a structural analysis of all the panels in the Oxgangs gable wall, including the panels that collapsed. These calculations showed that to meet the required wind-loadings, the collapsed panels would not only have had required to be properly restrained on all four sides, including the use of the missing head restraints, but would also have required additional stiffening in the form of either bed joint reinforcement or windposts.

9.2.37 This confirmed the conclusion reached separately, following their analysis of these panels, by Goodson Associates, the structural engineers appointed by Galliford Try to undertake the design of the remedial work to Oxgangs School. To satisfy this requirement, Goodson Associates specified the incorporation of bed joint reinforcement at 225mm centres to the brickwork panels in the rebuilding of the external leaf of the collapsed gable wall.

9.2.38 WSP did not agree with these findings and advised the Inquiry that they:

"have carried out our own calculations on the wall panels in the wall that collapsed. This was done for the wall construction as designed by WSP and we can confirm that our calculations demonstrate that the panels provide suitable capacity."

9.2.39 The Inquiry requested sight of these calculations to allow the design parameters used and methodology adopted to be reviewed against the independent calculations, but WSP advised that were unable to release this information for contractual reasons.

9.2.40 In examining the original 'construction status' drawings for Oxgangs school, that were provided to the Inquiry by Galliford Try, the Inquiry established that while the drawings produced by structural engineers WSP, showed the requirement for bed joint reinforcement and windposts to be incorporated into other walls of the school, no requirement for either component was shown on the drawings for the panels that collapsed.

9.2.41 If bed joint reinforcement had been specified and built into the outer brick leaf of the gable wall, this would have stiffened the panel, helping to hold it together, and may have to some small degree compensated for the inadequate embedment of the wall ties, making the panel slightly more capable of resisting the suction force of the wind. However, the structural integrity of the wall and the contribution of the bed joint reinforcement to the two leaves of the wall acting as one single element, depends on the two leaves being adequately tied together by the wall ties, which due to the lack of embedment was not the case.

9.2.42 The discovery of the absence of the specified head restraints in this wall was made by Galliford Try as they were commencing their programme of installation of remedial wall ties. The type of head restraint that had been specified by the original design team required both inner and outer leaves of the cavity wall to be tied back to the steel beams at 900 centres along their length.

9.2.43 As well as tying the individual leaves to the beam, this type of head restraint would have also provided a row of additional wall ties connecting inner and outer leaf along the top of the wall panels. While the fundamental fault remains the lack of embedment of the general wall ties, the failure to install these restraints meant that, in the circumstances of the storm, a somewhat greater loading than would have otherwise been the case, was required to be borne by the inadequately embedded wall ties, thus again contributing to the cause of the collapse of the inadequately tied outer leaf.

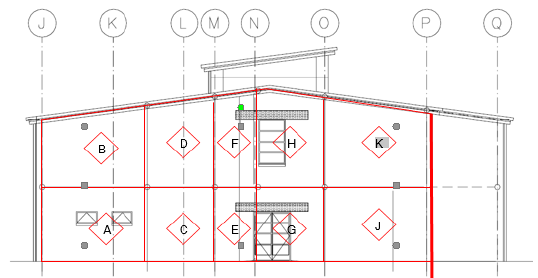

9.2.44 The gable affected by the collapse is illustrated below. Panels A, B, C, D, F and H were affected by the collapse.

9.2.45 As previously mentioned, after being appointed by Galliford Try, Goodson Associates undertook calculations to check the design of the wall panels at Oxgangs School, including panel 'B' as shown on the drawing below. These calculations together with some of the construction drawings for the Phase 2 that had been provided to Galliford Try by WSP were made available to the Inquiry. The calculations showed that panel 'B' would have failed the required wind loadings test, unless in addition to restraints on all four sides, additional strengthening of the panel was provided in the form of windposts or bed joint reinforcement.

9.2.46 This assessment found that the same issues, in relation to inadequacies in the structural design of panel 'B', applied to panel 'K' which would also fail to satisfy the required wind loading. Further calculations indicated that the design of panel 'H' would equally have failed.

9.2.47 The structural engineering advisor to this Inquiry undertook a similar detailed assessment of the panels in the same gable at Oxgangs using the "Construction" status drawings released to the Inquiry by Galliford Try and came to the same conclusions in relation to inadequacies in the design of panels 'B', 'K', and 'H '.

9.2.48 The remedial designs developed by Goodson Associates and implemented by Galliford Try satisfactorily addressed these issues.

Image 24: Structural construction drawing.

9.2.49 From the photographs of the bricks from the collapsed wall lying on the ground and of the exposed outer face of the inner blockwork leaf, it is reasonably apparent that neither bed joint reinforcement or wind posts were built in as part of the original construction of the wall. This was in accordance with the information on the structural 'construction drawings' as produced by WSP and provided to the Inquiry by Galliford Try, which showed no requirement for either.

9.2.50 It is the conclusion of the Inquiry that in addition to the lack of embedment of wall ties, as the primary cause of the collapse, there was a failure to install the head restraints as specified in the design documentation, the absence of which may have also contributed to the collapse of the panels.

9.2.51 It is also the conclusion of the Inquiry based on the calculations undertaken by Goodson Associates, and on the independently undertaken calculations by the structural engineering advisor to the Inquiry, that the structural design of panel B, the collapsed panel, would appear to be inadequate. (As previously stated, WSP have advised the Inquiry that they do not agree with this conclusion).

9.2.52 While this was not the primary cause of the collapse of the panel, the absence of bed joint reinforcement in this gable wall, despite being specified by WSP elsewhere in the exterior walls of Oxgangs School, may also have contributed to the failure of the panel.

9.2.53 The following possible causes in construction projects in general, rather than specifically in the case of these schools, of failures to install specified components such as head restraints were put forward by a number of witnesses, in each case based on their considerable experience of working in the construction industry.

• The information provided by the design team may not have been clear as to what was required.

• The information provided to the sub-contractor by the main contractor may not have been complete either for pricing by the sub-contractor or for implementation on site.

• The information in relation to the head restraints provided by the subcontractor to the specific brick-laying squad or bricklayer may not have been complete or sufficiently clear.

• The number of head restraints may have been intentionally reduced to reduce costs.

• The bricklayers, who were generally paid by the area of wall they completed in a day and not for the number of hours they had worked, may have omitted the head restraints as the installation of restraint fittings can significantly slow up the rate at which bricks can be laid and hence the amount the bricklayers could earn in a day.

• The bricklayers involved may not have had the requisite skills necessary to install the head restraints or were not aware of the implications of omitting them.

9.2.54 The Inquiry would wish to emphasise that these potential reasons for the missing head restraints were offered by witnesses as examples of possible scenarios that could have led to their omission and there is no definitive evidence to support these possible causes as having occurred.

9.2.55 However, some witnesses gave evidence which lent support to the list of possible reasons. This included evidence given to the Inquiry by a senior qualified structural engineer who advised that, at the time of the design and construction of the PPP1 schools, he had been the Technical Director of WSP responsible for the delivery of the structural engineering services in relation to the PPP1 schools. He is no longer a member of staff of WSP, having left the company some years ago.

9.2.56 In relation to the provision of secondary steelwork he advised the Inquiry that he thought:

"At the time the sub-contractors were pricing the jobs, that only architects' drawings had been available, as the level of secondary steelwork had not been fully developed and therefore may not have been allowed for in the costs agreed."

9.2.57 He added that he recalled:

"As the design was developed there had been heated arguments regarding the extent of secondary steelwork needed on the project."

9.2.58 However, he also expressed his confidence that the design had been undertaken very thoroughly and diligently. He specifically advised the Inquiry that in his opinion WSP had been particularly thorough in defining bed joint reinforcement requirements, although he did not know what had been given to the bricklayer. He added that a bricklayer may not think to ask for structural drawings.

9.2.59 When asked on whose drawings he thought that these types of restraint and reinforcement details should be shown, he noted that in his opinion there was a reluctance for architects to show these details on their drawings due to concerns about attracting liability.

9.2.60 This view concurred with the evidence provided by the current Director of Holmes Miller Architects, who had been involved in the projects and had advised the Inquiry that he would rely on the information in relation to the requirement for head restraints and bed joint reinforcement being properly provided on the structural engineers' drawings and in the specifications.

9.2.61 Further to this point, the ex-WSP Director advised the Inquiry that before qualifying as a structural engineer he had himself worked as a bricklayer for about eight years and he could not recall having been given structural engineers' drawings, normally only having been provided with architects' elevations.

9.2.62 One of the two witnesses who attended the Inquiry as representatives of the Scottish Building Federation, who also was previously a bricklayer and is currently a Construction Director with a medium-sized construction company, echoed this view. He stated:

"We would emphasize though that a bricklayer will generally just build walls. A foreman should normally have access to all the drawings and use those to brief the bricklayer. The bricklaying squad would usually be given general plans and elevation drawings but may not be provided with all the additional details that may be available to the managers and supervisors. The squad won't necessarily ask for copies of all the available drawings. So, for example, unless they and the bricklayers are made aware or told that bed joint reinforcement or wall head restraints for that matter are required, they won't automatically know that it should be there and build it in."

9.2.63 Given the wide extent of failure to incorporate elements of reinforcement and restraint to the brick panels that were shown on engineers' drawings across the PPP1 schools, and the fact that these schools were built by a range of different contractors and subcontractors, it is perhaps appropriate that the construction industry reviews how effectively information is produced, coordinated, presented and communicated to contractors and to tradesmen on site so that there is clarity at all levels as to the precise requirements of the design.

9.2.64 Finally, in relation to identifying the cause of the collapse of the Oxgangs School wall, as several witnesses to the Inquiry stated, the quality of construction of a masonry wall is primarily determined by the competence of the bricklayer and the quality of the workmanship applied.

9.2.65 On this issue, there was virtual unanimity in the opinions expressed by witnesses from all sectors as regards the current parlous state of traditional skills such as bricklaying in today's construction industry and the lack of availability of high quality experienced bricklayers, many of whom have left the industry. Evidence suggested that, over at least the last twenty years, it has been increasingly difficult to attract young people to take up these trades, due to the nature of the work, the nature of the construction industry and the uncertainty of a continuity of employment.

9.2.66 In evidence to the Inquiry a Regional Manager of the Construction Training Board said:

"Sub-contractors are not often seen to be part of the team due to the way they are treated and the short periods that they are often involved on a project. There is little interest in the follow-on activities or trades. Bricklayers are often enticed to move on through better rates which reduces their feeling of ownership on a project."

9.2.67 The Inquiry is of the view that, given the widespread nature of similar defective construction across the 17 PPP1 projects, undertaken by bricklayers from different sub-contracting companies, and from different squads within these companies, there is evidence of a problem in ensuring the appropriate quality in this fundamental area of construction. The construction industry needs to re-examine its approach to the recruitment, training, appointment, means of remuneration, vetting, supervision and quality assurance of bricklayers.