9.3 REASON FOR THE CLOSURES OF THE SCHOOLS

9.3.1 Section 5 of this Report has set out the chronology of events which ultimately led up to the decision on 8th April 2016 to close all the schools with immediate effect.

9.3.2 There were in fact three separate occasions of closures of schools:

• the closure of Oxgangs School on 29th January 2016, the day of the collapse of the gable wall;

• the closure of the three remaining Phase 2 schools in the week commencing 14th March 2016, following initial survey reports of evidence of similar lack of embedment of wall ties in these schools; and

• the closure of all the PPP1 schools with effect from 11th April 2016 following the Council being advised that it had been discovered that required head restraints were missing.

9.3.3 It is the view of the Inquiry that the decision to close Oxgangs School on the day of the collapse was entirely reasonable and appropriate. At this stage the Council did not know the cause of the collapse, other than an assumption that it was related to the strong winds associated with Storm Gertrude.

9.3.4 Oxgangs School reopened on Tuesday 2nd February after temporary shoring was installed to prevent any potential further collapse of the now exposed remaining inner leaf of the gable cavity wall.

9.3.5 In early March, the Council were advised that the outcome of the investigation into the collapse of the gable wall, which investigation was at that time restricted to solely the wall in question, had determined that the primary cause of the collapse was failure to properly embed many of the wall ties sufficiently into the bed joints of the outer brick face of the cavity wall.

9.3.6 During the week commencing 14th March 2016, decisions were taken to close all four Phase 2 schools at meetings of Council officers held to review information from the follow up intrusive surveys of the Phase 2 schools. The first survey received indicated the wide presence of inadequate wall tie embedment to the perimeter walls of Oxgangs School. The initial analysis of this information by WRD suggested that up to 50% of the wall ties in the School might not be sufficiently embedded.

9.3.7 The view of the Council officers was that the reported extent of potentially defective external brickwork wall panels around the complete perimeter of the school was such that it was impractical to seek to assure the safe operation of the school and grounds, even with the creation of exclusion zones. A decision was made to close Oxgangs School with effect from the next day, Wednesday 16th March 2016.

9.3.8 Information from further surveys advising of the presence of similar defects in the other three Phase 2 schools was received on 17th March. This quickly led to a decision to close all three of the other Phase 2 schools, Braidburn School, St. Peter's Primary and Firrhill High School with immediate effect from the morning of Friday 18th March 2016.

9.3.9 In the case of Firrhill High School, which had been an extension and refurbishment rather than a completely new school, it was decided that it would close from the 18th March 2016 to allow the undertaking of detailed structural surveys but re-open again on 21st March 2016 until 24th March 2016 when the Easter holiday period would commence.

9.3.10 The Inquiry was advised in evidence that the decision to close the schools was made purely as a result of the unwillingness of the Council to expose school children and staff to avoidable risk in light of the information provided as a result of the surveys. Effectively they had been advised that the same defect in construction, reported to have caused the collapse of the gable wall at Oxgangs, was also potentially widespread throughout the Phase 2 schools.

9.3.11 In a practical sense, it was also hoped that this short extension to the upcoming period of closure would allow the planned necessary remedial works to be completed prior to the end of the Easter holiday period and the reopening of the schools on 11th April 2016.

9.3.12 The Council also decided that, pending the results of the on-going surveys of the Phase 1 schools, these schools should remain open until the commencement of the Easter school holidays on 24th March 2016.

9.3.13 The Inquiry was advised that the logic behind the decision was that there was no evidence at that time to indicate that the defective installation of wall ties extended to the Phase 1 schools that had been built some two years before the Phase 2 schools. The fault was at this stage thought to be restricted to the four Phase 2 schools all of which had been built by the same contractor, Miller Construction. This reasonable assumption would be found to be incorrect within only a few days of this decision as the survey information on the Phase 1 schools began to emerge.

9.3.14 It should be noted that the perimeter walls of all the PPP1 schools had been subjected to a visual inspection undertaken by structural engineers immediately after the collapse of the Oxgangs wall. In no case had this led to concerns as to the presence of similar defects in the construction of the external walls of these schools as it was reported that there were no visible signs of structural distress in the masonry.

9.3.15 The subsequent discovery of significant defects, following intrusive investigations, would suggest that visual inspections are not sufficient on their own to provide an informed opinion as to the existence or otherwise of defects of this type.

9.3.16 It is the view of the Inquiry that it was an appropriate decision by the Council to close the four Phase 2 schools following information from the structural engineering consultants, who were acting for ESP, which suggested that up to 50% of the wall ties in the schools could be inadequately embedded in the external walls of these schools; this having previously been identified by the same consultants as the primary cause for the collapse of the wall at the Oxgangs School.

9.3.17 The last closure of the schools was the most significant, commencing on the 11th April 2016 and extending until it had been independently confirmed, in the case of each school, that the remedial works had rendered the buildings safe to reopen.

9.3.18 The circumstances leading up to the decision to close the schools were most unfortunate in terms of their timing. On 5th April 2016, ESP had presented letters of assurance as to the completion of all interim remedial measures previously agreed with the Council as necessary to provide a safe environment for pupils and staff due to return to school on 11th April 2016 after the Easter holiday period.

9.3.19 On 8th April 2016, after advising Council officers of the facts at a meeting that afternoon, ESP formally wrote to the Council confirming that the situation in relation to their ability to provide assurances as to the safety of the schools had changed. This had followed the discovery by Galliford Try employees, working on the Oxgangs School, of the apparent absence or inadequate spacing of head restraints that were normally required to connect the head of external cavity wall panels to the structural frame of buildings. The key extract from the ESP letter is repeated here for convenience of the reader:

"Shortly before noon today we were advised by the design and build contractor who is executing the remedial works at Oxgangs Primary and St. Peter's Primary that it had discovered serious defects as a result of which it has advised that these schools are no longer safe to occupy. Representatives of the Council were advised of the position this afternoon at a meeting with ourselves and the design and build contractor.

At present, it is impossible to confirm whether the same defect may exist at the other Estate buildings. In these circumstances, we are afraid that we have no option but to withdraw the confirmation contained in our letter of 5 April 2016 that the Estate buildings identified in the letter are safe for occupancy."

9.3.20 The receipt of a letter stating categorically in relation to Oxgangs and St. Peter's Schools that the Contractor for the schools had advised that 'these schools are no longer safe to occupy' on the Friday before the Monday when all the schools were due to open left the Council with little option other than to close these two schools with immediate effect.

9.3.21 The statement by ESP that they would 'have no option but to withdraw the confirmation contained in our letter of 5 April 2016 that the Estate buildings identified in the letter are safe for occupancy' was equally concerning to the Council. The letter of 5th April 2016 had in fact listed all the PPP1 schools, so this statement effectively advised the Council that ESP could no longer confirm the safety of any of the 17 PPP1 projects. The inference in the letter from ESP was that there was a possibility of the same absence of head restraints in the rest of the school buildings. Accordingly, they could not continue to provide the Council with an assurance that the buildings were safe for occupancy.

9.3.22 Up to this point, when the only problem that had been identified to the Council was the lack of embedment of wall ties, the Council had, somewhat reluctantly, agreed to accept the 2-staged approach to the completion of the remedial works, with the second stage planned to be undertaken during the normal period of closure of the schools over the summer.

9.3.23 Their agreement to this approach had followed consideration of both the survey information and the expert opinion provided. This indicated that any further failure due to lack of embedment of the outer leaf would most likely result in a similar collapse to that experienced with the Oxgangs School; that is, a collapse of the outer leaf brickwork towards the exterior of the building. Mitigation measures had been proposed that would ensure that any such collapses would be into exclusion zones which would be inaccessible to school children or members of the public.

9.3.24 The Report, on the 8th April, advising of the lack of head restraints in two of the Phase 2 schools and uncertainty as to whether it might be present in the Phase 1 schools, (subsequently found to be the case) changed the analysis of risk.

9.3.25 As will be explained further below, the information provided on 8th April 2016 to the Council suggested that the wall panels of the schools might not meet the requirements of the design codes. The absence of the head restraints meant that complete wall panels, both inner and outer leaves, may not have the necessary resistance to wind loading required to provide an assurance that the schools were safe.

9.3.26 If subjected to very strong winds of storm force, the absence of head restraints could contribute to the failure of both leaves of the cavity wall panels, not just the outer leaf. Both leaves of inadequately restrained wall panels, if exposed to strong wind pressure, could potentially collapse inwards as well as outwards. Such an eventuality could not be catered for by the proposed strategy that up to then had been accepted by the Council i.e. the creation of external exclusion zones.

9.3.27 The proposed strategy involved keeping pupils inside the buildings if they were already there when a wind warning was received. The adoption of this strategy would now have meant that those children, and the staff looking after them, could have been at risk from an inward collapse of masonry.

9.3.28 Also, if due to lack of embedment of wall ties there was to be a repetition of the collapse of only the external brickwork face of a wall panel in any re-occurrence of strong wind, the inner blockwork leaf, its structural integrity already significantly compromised by the lack of head restraints and loss of the contribution to overall structural capacity provided by the outer leaf, would now be fully exposed to further gusts, which it might then be unable to withstand.

9.3.29 Finally, the proposal from ESP that, if severe winds were expected and warnings were issued prior to the commencement of the school day, then pupils should remain at home, made the weather a determinant as to the provision or not of the essential continuity of access by pupils to education on designated schooldays. If the schools were not considered safe for pupils to enter during occasional periods of the high wind speeds that they had been required to be designed for, then the schools were effectively not fit for purpose.

9.3.30 It is the view of the Inquiry given:

• the already identified significant problem of poor embedment;

• the nature of the letter received from ESP withdrawing their previous confirmation that the schools were safe to occupy;

• knowledge of the dramatically reduced effective capacity of the brick panels to withstand wind-loading as a result of the omission of head restraints;

• the new awareness of the increased risk of an internal as well as external collapse of the cavity wall panels;

• the fact that there were only two days remaining before the schools were due to open; and

• the unacceptability of the continuity of teaching time over the remaining months being dependent on the weather

that the only practical and safe course of action in these circumstances was to close the schools in question, decant teachers and pupils elsewhere and commence an immediate programme of remediation.

9.3.31 The following provides a further explanation of the issues impacting on the necessity to close the schools.

9.3.32 The structural design of cavity wall panels is based upon the two leaves being held together by properly embedded wall ties to allow them to act as one in providing the required resistance to wind-loading. The capacity of the panel in this regard varies significantly depending on the number of sides on which the panels are effectively restrained. The overall general specification, which was applied to all the PPP1 schools, had required head restraints for connecting the cavity wall to the steel beams of the structural frame, and lateral restraints for fixing the cavity wall to the steel columns of the structural frame on either side of the panel. The wall panel is assumed to be restrained at its base.

9.3.33 The general specification document produced by the design team described the required centres at which restraints were to be fitted as 900mm. However, more detailed information on some of the limited number of construction drawings available to the Inquiry, indicated a requirement for head restraints to be fitted at 450mm centres rather than the 900mm centres in the specification.

9.3.34 It is a recognised convention, that where there is a difference between specification and drawing information, the contractor should seek confirmation from the design team as to which requirement should take precedent. The Inquiry was unable to establish if this had happened.

9.3.35 Under the National Building Specification approach that was adopted by the original design team, head restraints are described under the general heading of 'Wall Ties'. The relevant clauses produced by the design team were:

"211 WALL TIES

Fixing blockwork inner leaf to steel columns (1 required at alternate block course)

• To BS 1243, type MF2 Ties to be fitted with a de-bonding sleeve DBS2 by Metsec or equal where the blockwork panel between steel columns exceeds 6.0m in length

• Material/finish: Stainless steel

• Size: 75 x 40mm

212 WALL TIES

Fixing blockwork Inner leaf and Brick leaf to Steel Eaves Beam

• To BS 1243, type SAW-1-130 with ties type TWT-275 and TWT-130 at 900mm centres by Metsec or equal

• Material/finish: Stainless steel"

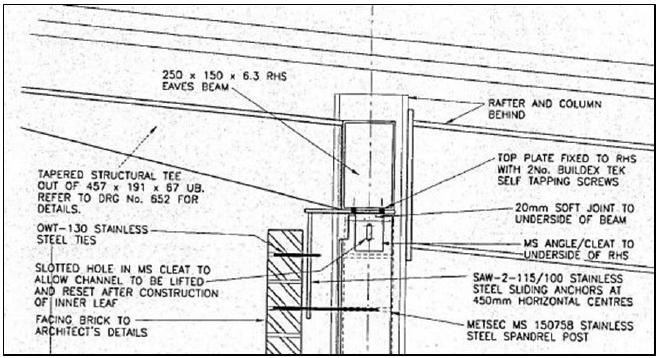

9.3.36 A drawing demonstrating the detailed application of the head restraint and its connections to the steel beam and the two leaves of the cavity wall is shown below in Diagram 8. This is an example of where the drawing shows a difference in the centres of the head restraints to that described in the general specification; 450mm centres as opposed to 900mm centres. This is one of the limited number of detailed drawings originally produced by WSP for use in the construction of the Royal High School, a Phase 1 PPP1 school, that ESP, Amey and the structural engineering advisers had access to. These copies of drawings were retrieved from the ESP archive. As previously stated in this Report they had not been provided by WSP to ESP.

9.3.37 The drawings below demonstrate the design team requirement for a three-part head restraint tie; the sliding anchors, SAW-2-115/100, of the head restraints to be fitted at 450mm centres to the underside of the steel beam with TEK screws; the one-way-tie, OWT-130, connecting the outer brickwork leaf to the sliding anchor; and the two-way-tie, TWT-275, (not notated but shown on the drawing) connecting both the outer brickwork leaf and the inner blockwork leaf to the sliding anchor. The 130 and 275 figures refer respectively to the lengths in millimetres of the one-way and two-way ties that are built into either one leaf or both leaves and connected to the sliding anchor which in turn this drawing shows to be required to be fixed to the overhead steel beam at 450mm centres.

9.3.38 This drawing shows how this type of head restraint not only ties the leaves to the steel beam but also helps tie the leaves to one another.

Diagram 8: Structural drawings for the Royal High School showing the requirement for head restraints tying steel beam to both inner and outer leaves of cavity wall.

9.3.39 The reports written in April 2016 by Goodson Associates describing the outcome of the intrusive surveys of the cavity walls at the Royal High School Edinburgh, which should have been built in accordance with the above drawing, state that in their examination of 39 of the 102 panels of brickwork, no head restraints whatsoever were found to be present in 13 of the 39 panels opened up. In another 13 panels of the 39, head restraints were found but their installation was reported to be defective.

9.3.40 In a further nine of the 39 panels, the head restraints were built in at 900mm centres. Only the final four of the 39 panels had restraints built in at 450mm centres as shown on the drawing.

9.3.41 If the wider spacing of the head restraints at 900mm centres is ignored, the results show that 67% of the panels tested would be defective. If we consider the wider spacing of 900mm as defective, then 90% rather than 67% of the panels tested would be rated defective.

9.3.42 In relation to this last point, Ancon, a leading manufacturer of these fittings, advise in their technical literature that a similar type of head restraint manufactured by them when fitted at 450mm centres provides a design resistance of 3429 Newtons/metre, whereas if it is fitted at 900 centres, the design resistance provided is halved to 1714 Newtons/metre.

9.3.43 The failure to install head restraints at all, would have reduced the capacity to resist wind-loading of one of the typical larger masonry panels found in schools by a factor of up to 45%. The results of the structural surveys, as previously shown, demonstrate the percentage of investigations which failed to find the required restraints in the various schools.

9.3.44 The Inquiry is of the view that the disparity between what was built and what was designed, in relation to the lack of head restraints, must ultimately be the responsibility of the design and build contractors, AMJV for the Phase 1 schools and Miller Construction for the Phase 2 schools.

9.3.45 Following the analysis by the Inquiry of the information provided in the survey reports and in the limited number of drawings and specifications made available to the Inquiry, a further concerning aspect of the construction of the schools was identified. This related to the issue of the incorporation or otherwise of bed joint reinforcement, an explanation of the typical use of which has already been provided in Section 5 of this Report.

9.3.46 The general specification produced by the design team for the PPP1 schools included a specification for the use of bed joint reinforcement. The relevant clause read as follows:

"271 JOINT REINFORCEMENT FOR 365mm CAVITY WALLS

• Manufacturer and reference: BRC Brickforce SBF35-50

• Material: Stainless steel

• Width: Approximately 40-50mm less in width than wall or leaf

• Lay on an even bed of mortar in a continuous strip with 225mm laps at joints and full laps at angles. Keep back 20mm from face of external work, 12mm back from face of internal work and finish mortar join to normal thickness."

9.3.47 This specification clause does not provide information as to the extent of bed joint reinforcement that is to be used in the cavity walls. This should be provided either in annotated drawings of the elevations of the walls or through a detailed descriptive schedule of the work required for each panel. This information would have to include details in terms of at what centres or number of courses the bed joint reinforcement was required to be installed in the case of both the blockwork inner and brick and blockwork outer leaves of each panel of the cavity wall. Across many of the schools surveyed it was found on investigation that the bed joint reinforcement specified had either not been installed at all or had not been installed consistent with the requirements of the specification.

9.3.48 It is the view of the Inquiry that, as in the case of the missing head restraints, the failure to incorporate the specified bed joint reinforcement in accordance with the design, impacted significantly on the capacity of the panels to resist the required levels of wind-loading and undermined the integrity of the structural design of the external walls of the schools.

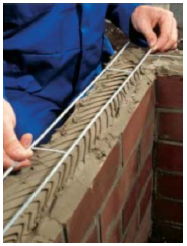

Image 25: Example of bed joint reinforcement

9.3.49 Amongst the design team structural engineers' drawings provided to the Inquiry, there are examples of drawings providing the additional information required by the bricklaying sub-contractor to properly locate where and to what extent the bed joint reinforcement was required. It is not however possible to confirm whether this information was comprehensively provided in all cases due to the limited receipt of this type of information by the Inquiry or, as a result, specifically to what extent the design engineer had specified it in all schools.

9.3.50 This does however show that the structural engineers had viewed the use of bed joint reinforcement as a key component of their design strategy in addressing the issue of the required capacity of panels to withstand wind-loadings.

9.3.51 Unfortunately, from comparing the information provided and the results of the intrusive structural surveys, it is again evident that there were failures on the part of the construction teams to construct the buildings in accordance with the required designs.