Chapter Seven Issues Which Determine Performance

7.1 Unequivocal evidence about performance on site, and how the British construction industry compares with other countries, is hard to find. Some surveys have been carried out, which may show that British performance is below that of some of our international competitors. Some large clients certainly believe this to be so, and have taken steps to introduce new techniques, systems of procurement and research to raise the standards of British construction. For example:

1. Lynton plc found that the cost of producing a typical US office building in North Carolina to be 32% lower than a similar building at Heathrow. The divergence arose from differences in specification levels and greater use of standard components in the USA. (Source: "The UK Construction Challenge", 1993.)

2. Stanhope reported that during the period 1985 to 1991 they regularly achieved construction savings of around 30% compared to industry norms. They are looking for further significant reductions, setting specific targets and involved in benchmarking research in the USA and Japan. They are currently studying possible over-specification of floor loadings and mechanical and electrical systems. They are also looking to extensive use of Prefabrication and modulisation to improve on-site efficiency. (Source: "Setting Standards in the Construction Industry", October 1993.)

3. McDonald's Restaurants Ltd has used a great deal of off-site prefabrication for its fast food outlets. It has reduced cost and time of construction in the UK over the last five years by 60%, and on-site construction times from 115 to 15 days. It uses modular techniques and treats production as an engineering exercise. It is looking for further improvements, including standardisation of foundations. It agrees on a yearly programme with producers so as to build up familiarity, team work and performance (source: McDonald's Restaurants Ltd).

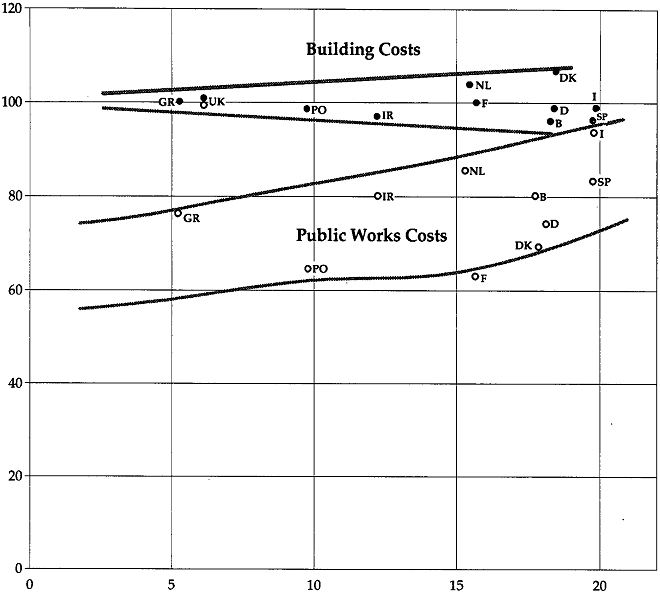

7.2 "Strategies for the European Construction Sector - A Programme for Change", the report prepared by W S Atkins for the European Commission, found the United Kingdom to have high construction costs compared to other EU countries but almost the lowest wage costs. Japan, after calculation of purchasing power parity (PPP) to minimise differences in exchange rates, is shown to have the lowest cost for building compared with the EC and USA. These findings are set out in tables 11 and 12. Some of the differences may be accounted for by different levels of specifications.

| Buildings | Public Works | Total at PPP | |||

| Market Rate | at PPP | Market Rate | at PPP | ||

| UK | 100 | 100 | 100 | 100 | 200 |

| Netherlands | 105 | 105 | 87 | 86 | 191 |

| Italy | 84 | 97 | 79 | 92 | 189 |

| Denmark | 117 | 107 | 79 | 72 | 181 |

| Spain | 73 | 94 | 65 | 84 | 178 |

| Ireland | 82 | 96 | 70 | 81 | 177 |

| Greece | 70 | 100 | 53 | 76 | 176 |

| Belgium | 82 | 96 | 68 | 79 | 175 |

| Germany, | 97 | 96 | 75 | 74 | 170 |

| France | 81 | 101 | 54 | 67 | 168 |

| Portugal | 53 | 98 | 34 | 63 | 161 |

| EC Median | 82 | 98 | 75 | 79 | 177 |

| Turkey | 35 | na | 20 | na | na |

| Japan | 86 | 77 | 98 | 88 | 165 |

| USA | 73 | 108 | 76 | 112 | 220 |

Source: WS Atkinsfrom OECD data, Table 5.1 of "Strategies for the European Construction Industry -

TABLE 12: RELATIONSHIP BETWEEN PROJECT COSTS AND LABOUR COSTS, EC COUNTRIES

Cost index (UK=100) at PPP

Labour cost (ECU/hour) at PPP

___________________________________________________________________________

Source: Figure 5.4, from "Strategies for the European Construction Industry - A Programme for Change" prepared by W S Atkins for the European Commission, published by the European Commission, May 1994.

7.3 Some performance issues can be, and are being, addressed through new procurement routes or new technology, such as Knowledge Based Engineering. There is scope for improvements through greater standardisation of components and design details and more off-site prefabrication. This will require effective teamwork by designers, contractors, subcontractors and manufacturers. Specialist engineering contractors believe that better collaboration in design between consulting engineer and specialist could produce a target cost saving of 20%.51 But removing other obstacles to progress involves a new look at competence, training and education, research and development.

___________________________________________________________________________

51 c/f Paper by Mr Martin Davis to the SPIM conference on construction management, 25th March 1994, in which a detailed breakdown of the 20% calculation is given.

- Competence of Contractors: Registration/Accreditation of Firms

- CDM

- Operatives

- Training and Recruitment

- Recommendation 20: Training

- Other Training Issues

- The Image of the Industry

- Recommendations 21.1 - 21.2: Image of the Industry and Equal Opportunities

- Professional Education

- Recommendation 22: Professional Education

- Research & Development The Problem

- Research Strategy

- Funding by Levy

- Research and Information Initiative

- Recommendations 23.1 to 23.4: Research and Development

- Quality Assurance

- A Productivity Initiative

- Recommendation 24: Productivity Target