Unlock the benefits of industrialisation

Government and industry alike directly benefit from stable project pipelines, and effective use of portfolio management is the key to creating stability. With this stability and better coordinated buying power, governments can start to transition towards the industrialisation of the sector.19 This transition is long overdue and could result in productivity benefits of up to 60%.20

| Industrialisation will transform the infrastructure sector The current approach to infrastructure requires each infrastructure asset to be uniquely designed, built, and operated. However, like the shift from hand built automobiles to mass production led by Henry Ford and others, there is an opportunity to standardise components and approaches in infrastructure. This move to 'industrialisation' seeks to reverse the trend towards bespoke designs and move to a more consistent approach characterised by higher productivity. Infrastructure industrialisation involves the systematic adoption of highly efficient infrastructure production methods that emphasise the use of offsite manufacturing and automated component assembly processes.21 This differs from the current approach that favours bespoke designs, components, and parts installed for a single purpose. Learning from other sectors that have successfully traversed towards industrialisation, such as automotive and commercial aerospace, the infrastructure sector can move towards an environment with major productivity gains.22 The change will require systematic changes in design approaches, purchase arrangements, technology adoption, and commercial arrangements. |

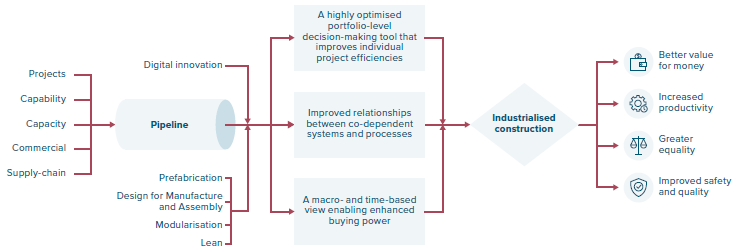

Through industrialisation, projects move from being regarded individually to being considered together as a 'system'. Governments can capture benefits from innovative concepts and approaches in planning, design, and delivery.

The opportunities include design reuse, standardised design elements, supply chain integration, 'lean' manufacturing and 'Six Sigma' techniques, modularisation, prefabrication, offsite construction, frame agreements, bulk procurement and digitisation.23

These can all be deployed to increase productivity, reduce waste and create higher-quality infrastructure for less.

For more information on opportunities for digitisation in the sector, see Reform 3.3 in this chapter.

Under industrialisation, small-scale improvements in production practices that are applied on a single project can be shared and expanded to similar projects in the same state, between states or even across the country.

This creates a multiplier effect, generating a positive impact on budgets and timelines for all projects (see Figure 3.1).

It is important to highlight that industrialising the infrastructure sector can help accelerate other necessary pursuits, notably decarbonisation, sustainability and resilience. For example, industrialisation can increase the uptake of building products with a lower environmental impact (such as high-strength concrete or eco-friendly cement binders) by using collective buying power and combining it with continuous improvement in materials management.24 Reaching the sector's full industrialisation potential for cost reduction and efficiency relies on the widespread adoption of modern approaches to infrastructure.

Together, governments and industry need to move away from bespoke design and construction processes. Governments should develop orchestrated infrastructure programs instead of individual projects and favour approaches and commercial models that maximise the use of modern methods of design and construction using standardised components.25

Figure 3.1: Taking a portfolio approach will improve infrastructure outcomes

Source: Adapted from Oltmann, J (2008)26