Framework ESI through Supply Chain Collaboration

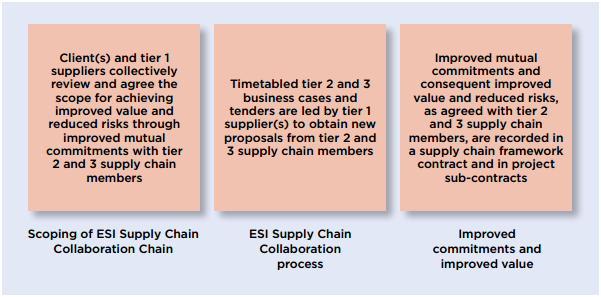

At framework level, ESI can reach tier 2 and 3 supply chain members through supplier-led 'Supply Chain Collaboration', a system which is designed to improve tier 2 and 3 commitments and contributions by reviewing, improving and potentially aggregating the supply chain relationships created by tier 1 suppliers for framework projects and programmes of work. The processes of Supply Chain Collaboration are summarised in Diagram 5 and are described in Cabinet Office guidance.

|

The Project Horizon Trial Project highways alliance reports that Supply Chain Collaboration led by Kier with Surrey County Council, Aggregate Industries and Marshall Surfacing generated agreed savings in excess of 12% over a period of five years in exchange for: ■ Visibility and continuity of larger scale, longer term work pipeline of work ■ Advance planning of work on each annual cycle ■ Prompt payment at all levels of the supply chain ■ Closer supply chain involvement in design and planning ■ Availability of storage facilities in client depots. |

|

The Project Horizon Trial Project highways alliance also reports qualitative benefits comprising: ■ Improved whole life value, including a ten-year warranty for materials and pavements ■ Improved quality control through joint risk management ■ Improved apprentice commitments by tier 2 and 3 supply chain members ■ Time savings through lean programming ■ Innovations that increased recycling and reduced landfill ■ No major remedial work required and no major health and safety incidents ■ Over 100 complimentary letters received from residents and Council members. |

Review participants comment that current frameworks can fail to reach local and regional SMEs because tier 2 and 3 supply chains are established by tier 1 suppliers who have little knowledge of local or regional markets and capabilities. Supply Chain Collaboration can ensure that tier 1 suppliers take account of the particular benefits that local and regional supply chain members can offer in terms of cost, quality, sustainability and other relevant factors.

Supply Chain Collaboration therefore provides a major breakthrough for central and local government and other public sector clients who wish to support local and regional economies without infringing public procurement regulations and without undertaking their own direct tier 2 and tier 3 procurements. The benefits of framework ESI through Supply Chain Collaboration are demonstrated in Annex 3 case studies 1, 2, 3, 4, 5, 6, 7, 8 and 9.

The processes of Supply Chain Collaboration are described in more detail in Annex 5. The benefits of Supply Chain Collaboration in optimising contributions from SMEs are described in Section 7.

Diagram 5: Structure of framework ESI through Supply Chain Collaboration

|

Recommendation 13: Improve economic, social and environmental outcomes through framework early supply chain involvement (ESI), using Supply Chain Collaboration systems in all framework contracts To maximise the improved value demonstrated by ESI in collaborative framework case studies, including efficiency savings, improved quality and safety, improved social value and reduced GHG emissions, this review recommends that framework providers, clients and managers use framework ESI to obtain and evaluate supplier and supply chain insights, innovations and proposals, including a contractual 'Supply Chain Collaboration' system through which to create strategic supply chain relationships that improve project outcomes. |

Specific actions include:

Framework strategy

■ Consider ways in which the framework can deliver client outcomes with improved value and reduced risk by formally engaging tier 1 suppliers alongside tier 2 and 3 supply chain members, strategically and in the pre-construction phase of framework projects.

■ Consider the benefits to the framework of using Supply Chain Collaboration.

■ Consider how ESI can obtain SME insights into MMC, innovative technologies, social value, eradicating Modern Slavery and ways to minimise the GHG footprint of proposed solutions across their whole lifecycle.

■ Involve prospective tier 1 contractors and prospective tier 2 and 3 supply chain members in developing the framework business case.

Framework procurement

■ Evaluate supplier ESI proposals:

■ to reduce end-to-end programme timescales, identify opportunities, mitigate risks, develop solutions to the right quality levels and increase safety

■ to work collaboratively alongside other tier 1 suppliers and tier 2 and 3 supply chain members

■ to implement Supply Chain Collaboration systems for unlocking additional value and innovations.

Framework contract

■ Structure the systems for call-off, value improvement and risk management, and the framework pre-construction services agreements, so as to:

■ formally engage tier 1 contractors alongside the tier 2 and 3 sub-contractors and suppliers at a strategic level and in the pre-construction phase of framework projects

■ access industry experts' knowledge and experience in all tiers of the supply chain early in the project or programme lifecycle

■ collaboratively manage the relationships and interdependencies of supply chain members

■ state the Supply Chain Collaboration systems for unlocking additional value and innovations.